MedEco XGB

The bioplastic for rigid extrusion components with a particularly non-slip surface.

Process characteristics

- Very good workability

- Low temperatures - high energy savings

- Processing instructions

Sustainability aspects

- 99% bio-based

- Very low footprint

- Biodegradable according to EN 13432

- Recycling options

- Sustainability factsheet

Applications

Our MedEco XGB is ideal for applications that require a rigid, non-slip material with high surface hardness.

- Bottles and cans

- Blister packaging

- Pipes and profiles

CO2e reduction compared to

PET

0

%

PP

0

%

HDPE

0

%

ABS

0

%

Scope: CO2 savings potential for the compound in cradle-to-gate.

Concrete results depend on other factors such as product geometry and processing technology.

We are happy to calculate the potential for your application.

Products & Processes

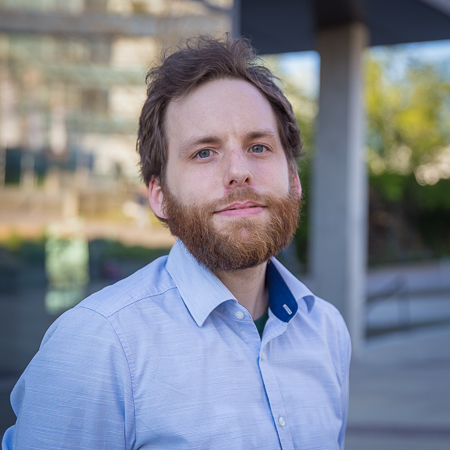

“High productivity, dimensional stability and a wonderfully comfortable surface. Your new sustainable material for opaque blisters and profiles.”

Book a consultation!

Together, we take a look at how to pragmatically and easily become greener in your application, and what sustainability potential you can leverage with us.